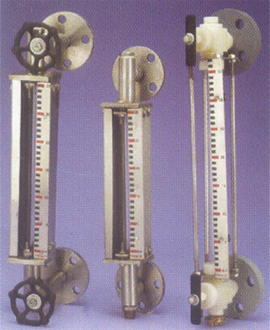

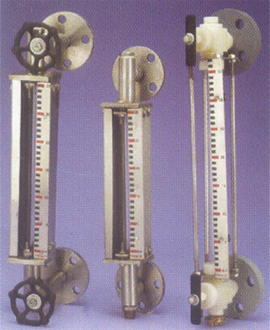

Tubular Level Gauge

With more than 2 decades of experience, we are today one of the leading manufactures, suppliers and dealers in India of Tubular Level Gauge. It is used for visual liquid level indication and is the most commonly used instrument in the process industry. It is a simple and reliable device for level reading in atmospheric or pressurized tank applications. It is mounted parallel, along the side of the tank, so as to form a closed loop. As the process level fluctuates, the level in the transparent glass tube changes accordingly and gives local level indication. The TLG manufactured by VEKSLER incorporates correct design, rugged construction, proper manufacturing techniques, skilled workmanship to give dependable performance and long service life. Material integrity is assured through strict compliance of chemical composition analysis in a standard laboratory. With more than 2 decades of experience, we are today one of the leading manufactures, suppliers and dealers in India of Tubular Level Gauge. It is used for visual liquid level indication and is the most commonly used instrument in the process industry. It is a simple and reliable device for level reading in atmospheric or pressurized tank applications. It is mounted parallel, along the side of the tank, so as to form a closed loop. As the process level fluctuates, the level in the transparent glass tube changes accordingly and gives local level indication. The TLG manufactured by VEKSLER incorporates correct design, rugged construction, proper manufacturing techniques, skilled workmanship to give dependable performance and long service life. Material integrity is assured through strict compliance of chemical composition analysis in a standard laboratory.Features

- Choice of Tie Rod or C-Frame Construction.

- With or withour isolating valve.

- Material integrity assured through strict compliance of chemical composition analysis in a Standard Laboratory.

- H Grade Borosilicate glass tube 16/19/25 mm outer dia with Teflon Packing.

- Glass tube an be removed onlien i.e. without disconnection from vessel

- Standard Connection: 1/2" / 3/4" / 1" Flange drilled to ASA 150#, others on request

- Alluminium/SS scale with 5 mm resolution as standard and 1 mm on request.

- Drain Plug 1/2" Vent Plug 3/4" as std and drain/vent valve as optional

- Safety Ball check device(optional).

- Defrost/illuminator available on request.

- Hydro test pressure: 12 KG/cm2, 100 Deg C max working temperature.

- Tie Rod Construction is light' and permits 360C visibility.

- C-Frame construction is robust and permits observation from Front & Rear.

- Both constructions are available in integral or inline arrangements.

- High quality, H grade borosilicate glass tube in 16/19/25mm outer dia is used.

- Available in single length having c/c distance = 1600 mm. Extended lengths are provided by coupling several tubes or gauge assemblies in series.

- Gland packing design provides tension free tube installation to achieve zero leakage. It also enables glass removal for replacement or cleaning without dismantling the gauge or disconnection from the vessel.

- Transparent Acrylic Plate mounted on C-Frame/Acrylic Pipe or slotted metallic pipe clamped on Tie Rod as glass protector can be provided if required, for additional safety to glass & personnel.

- Adjustable proximity/reed switch arrangement for level sensing with alarm relays.

Specifications

| Construction |

Tie rod or C-frame guards in MS/SS |

| Gauge |

16 mm/ 19 mm OD (normal liquids) & 25 mm OD (Viscous liquids) heavy walled borosilicate glass in single length of 1500 mm.

|

| Packing |

Neoprene, Silicon, viton or PTFE to suit required temp./corrosive conditions.

|

| Material |

MS, CS, SS304, SS316 & PP as standard. |

| Isolating Valves |

Straight/Offset needle valve for integral type and diaphragm/Ball/needle valve for inline type.

|

| C/C Distance |

1600 mm in single tube length. Extended range by coupling 2 or more tubes through a coupler.

|

| Vessel Connection |

Flanged, screwed or industrial fittings in vertical or Horizontal orientation.

|

| Vent/Drain |

NPT Drain and Vent plug or valve as required. |

| Visibility |

approx 150 mm less than the CC distance |

| Max. Pressure |

0 12 kg/cm |

| Max. Temperature |

0 - 200C depending upon gland packing/gasket material |

| Scale |

Alluminium/Stainless steel with LC 5 mm as standard LC of 1mm on request.

|

| Glass Protector |

Slotted Al or MS pipe/Acrylic tube for tie rod construction and acrylic shields for C-frame construction, if required.

|

|

With more than 2 decades of experience, we are today one of the leading manufactures, suppliers and dealers in India of Tubular Level Gauge. It is used for visual liquid level indication and is the most commonly used instrument in the process industry. It is a simple and reliable device for level reading in atmospheric or pressurized tank applications. It is mounted parallel, along the side of the tank, so as to form a closed loop. As the process level fluctuates, the level in the transparent glass tube changes accordingly and gives local level indication. The TLG manufactured by VEKSLER incorporates correct design, rugged construction, proper manufacturing techniques, skilled workmanship to give dependable performance and long service life. Material integrity is assured through strict compliance of chemical composition analysis in a standard laboratory.

With more than 2 decades of experience, we are today one of the leading manufactures, suppliers and dealers in India of Tubular Level Gauge. It is used for visual liquid level indication and is the most commonly used instrument in the process industry. It is a simple and reliable device for level reading in atmospheric or pressurized tank applications. It is mounted parallel, along the side of the tank, so as to form a closed loop. As the process level fluctuates, the level in the transparent glass tube changes accordingly and gives local level indication. The TLG manufactured by VEKSLER incorporates correct design, rugged construction, proper manufacturing techniques, skilled workmanship to give dependable performance and long service life. Material integrity is assured through strict compliance of chemical composition analysis in a standard laboratory.